Flexibility and Freedom of Choice for Machine Builders at the Heart of Berghof Automation

How important is flexibility for machine builders? According to Matthias Geissler of Berghof Automation, this theme is becoming increasingly significant, even beyond the current scarcity. We talked with him about Berghof, a number of exciting new products, and why they chose VARIODRIVE as their distributor in the Netherlands.

“Berghof Automation products are unique in many ways, one of which is the speed at which we update the software of our products. This means that machine builders can always quickly benefit from the latest features of the integrated CODESYS software. With competing products, this can sometimes take years.”

Matthias Geissler, Head of Sales at Berghof Automation, emphasizes in his story the possibilities of their products for machine builders. He has been working at Berghof for several years and previously worked in the same market for a wholesaler and then another manufacturer of electronic control units and Human Machine Interfaces (HMI). Why did he choose Berghof?

“Within Berghof, attention is not only focused on the world around us, but also on the employees and what they consider a healthy company. The latter means that the group ensures that the companies can always stay on course, even in tougher times like the recent Corona crisis. Our R&D teams continue to work on product development while the teams remain focused on our goals. This long-term vision also resonates well with me.”

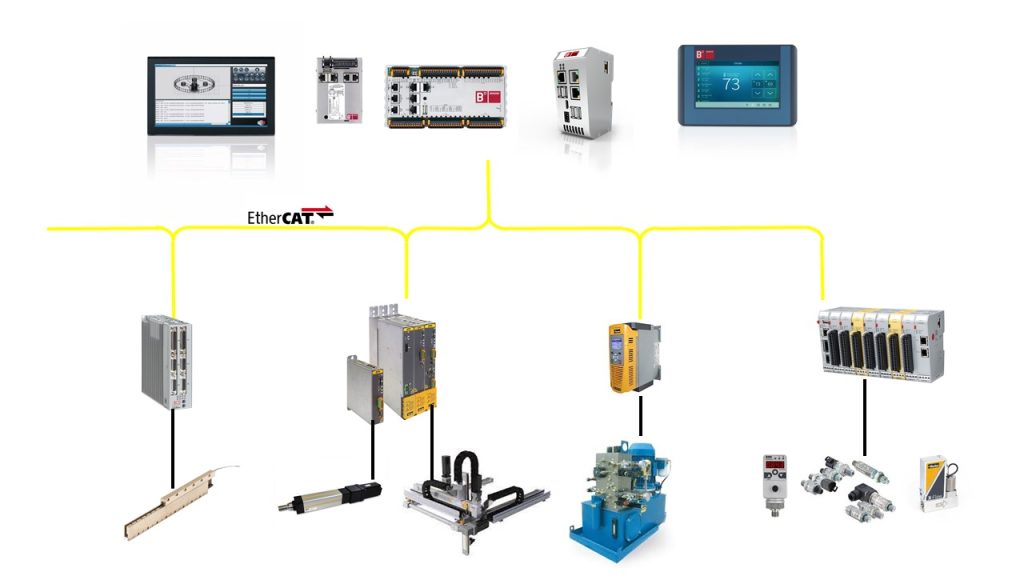

Berghof Automation Products

Berghof was founded in 1966 by a scientist and philanthropist, Georg Zundel. The initial activity was the development of a pressure compensation diaphragm, which formed the basis for Berghof’s Fluoroplastic Technology division, which remains a leading specialist in that field today. Over the years, new technologically advanced divisions were added, now totaling eight in the group. Berghof Automation originated after the development of the first freely programmable microprocessor controller for industrial applications.

This freedom of programmability is still the foundation of Berghof products. The advanced control solutions – such as modular and compact control systems, touch panels, and safety systems – are all natively implemented with CODESYS. This integrated, hardware-independent programming package for industrial automation provides machine builders with maximum freedom regarding components, while the open software remains a constant factor.

Raspberry Pi for Industry and Machine Builders

“We recently introduced new products based on Raspberry Pi, the B-Nimis MC-Pi and the B-Nimis BC-Pi. While Raspberry Pi is primarily used by hobbyists, these new products are ideal for industrial applications. They are not only high-performance CODESYS controllers but also flexible IPC solutions for realizing IIoT, motion, and automation projects.

The MC-Pi is equipped with software tailored specifically to CODESYS, delivering optimal performance as a controller, while the BC-Pi offers tremendous versatility due to its fully open software. Even in these products, the flexibility and choice for machine builders remain central.”

Developments in the Field of Machine Control

“At Berghof, we see the shift towards open systems as a significant development. Currently, the market is dealing with global component shortages. With our open products and software, we offer an ideal alternative for manufacturers whose existing components are simply not available. We’ve noticed that many machine builders are approaching us for this reason, and we expect this trend to continue in the future. More and more people understand the value of flexibility, both in terms of products and suppliers. Berghof has been enabling this from the very beginning.

Another important development is the collaborative development of hardware and software by a single entity. A machine builder then has a single point of contact during both the development process and the maintenance of the application. Of course, this requires parties that possess knowledge of both hardware and software.”

VARIODRIVE is a Berghof Partner

“We chose VARIODRIVE because, first and foremost, they have a lot of technical expertise in-house. Their people are capable of combining their motion control knowledge with our products to arrive at the optimal solution for the machine builder and provide the necessary support.

Additionally, we also collaborate closely with VARIODRIVE on aspects such as workshops, knowledge sharing, and aligning product developments. We want to incorporate their knowledge and experience into our developments, and we provide intensive support to VARIODRIVE in implementing our products. Together, we can deliver exceptional service and quality.”

[fl_builder_insert_layout id=11234]

Integrated HMI Controller

When asked about what excites him for the future, Matthias immediately referred to Berghof’s work with the Raspberry Pi:

“In the second half of the year, we will be introducing a particularly comprehensive product, an integrated Human Machine Interface and computing module in one. This product even includes wireless and Bluetooth connectivity, allowing machine builders to achieve not just two, but three benefits in one go. Naturally, it comes with the connectivity options and native CODESYS integration that customers expect from a Berghof product. Unfortunately, I can’t reveal much more about it; we’ll be unveiling this product for the first time at SPS in Nuremberg [November 8, 2022].”

VARIODRIVE is a proud partner of Berghof. The open architecture of Berghof products, combined with the hardware-independent programming package, provides engineers with many more options when realizing an application. We would be happy to share more about this through various concrete examples and cases.