Modern sensor technology plays a central role in the smart integration of R+W.

Leading coupling manufacturer R+W recently introduced a SMART coupling for Industry 4.0 applications, the IPK. We spoke with Managing Director Frank Kronmüller about the role of data in the company’s strategy and applications. As a long-standing partner of R+W, VARIODRIVE is the representative of the brand in the Netherlands, and with this article, we aim to highlight the strength of this German market leader.

R+W Couplings

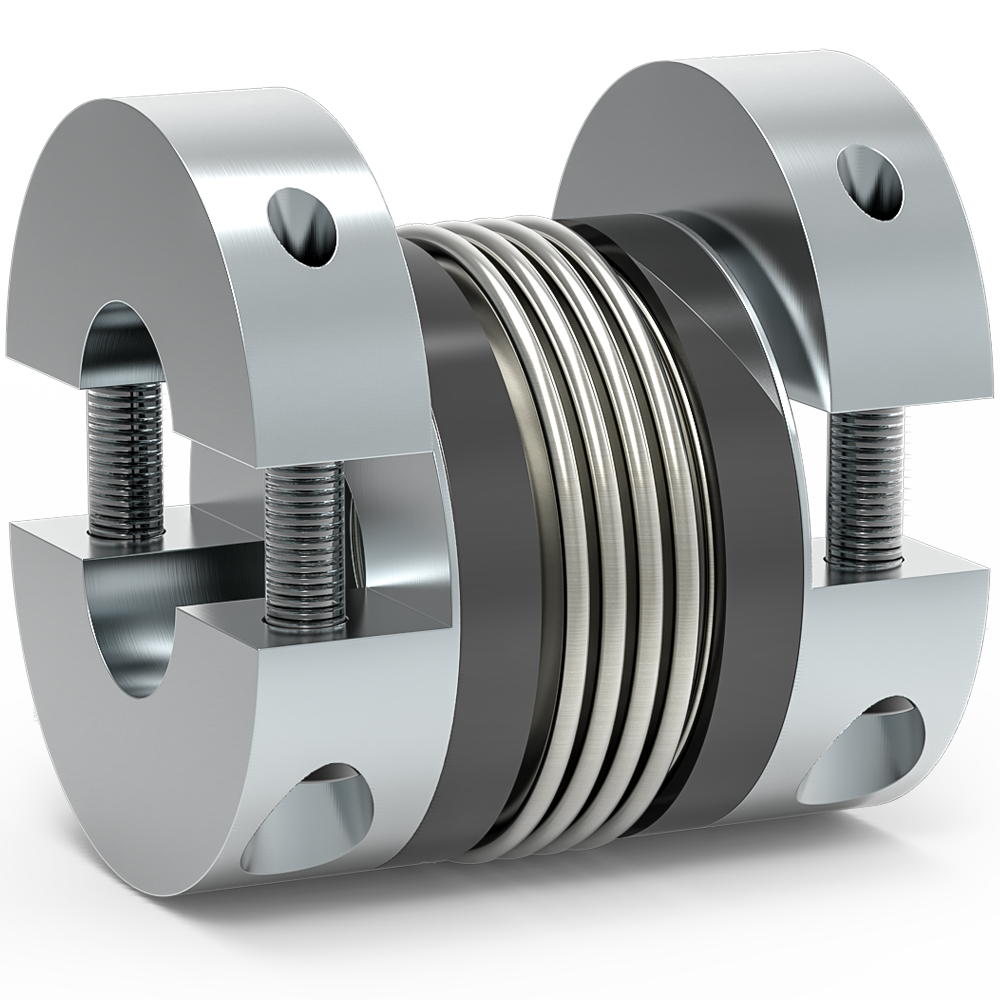

Although the official name is R+W Antriebselemente, the company is widely known as R+W Couplings. R+W describes its couplings as the “hidden champions” that ensure reliable transmission. The range of couplings produced by R+W is unparalleled, offering solutions from 0.05Nm to 2080kNm, including bellows, claw, lamella, safety couplings, and intermediate shafts. The best solution is available for every application, and if a coupling doesn’t exist, it’s custom-made for the customer. The fact that even astronauts on the International Space Station work with custom-made safety couplings from this German manufacturer underscores its reputation.

The company has a clear vision for its growth in the coming years. We discuss this with Frank Kronmüller, one of the three Managing Directors, primarily responsible for the organization’s marketing and sales strategy.

“Our strategy aims to provide clear customer benefits; they collaborate with a more responsive and agile organization that can deliver on its promises. This ultimately determines our competitive position. An essential prerequisite for this is that we become a data-driven organization and apply this approach to our products as well. This allows us to further distinguish our offering while making the company more efficient (LEAN). Naturally, our partners also play a significant role in this.”

Refined knowledge of mechanical drivetrains.

“VARIODRIVE is the example of a partner we would like to have in every country. We truly consider them a partner, even a Premium Partner. VARIODRIVE is unique because they possess not only significant knowledge and experience in the ‘electrical side’ of drivetrain technology but also hold refined expertise on the mechanical side. They oversee everything from control/servo controllers to the mechanical coupling at the other end of the drivetrain. Therefore, they are the representative of R+W in the Netherlands, and we are building and relying on that relationship.

The trust works both ways – VARIODRIVE provides us with their market, application, and customer knowledge, and we support them with our global expertise and specialization in mechanical drivetrains. We provide training, coaching, and grant them access to our product information and drawings – all to ensure they are fully equipped to use our product for their clients. Sometimes this even means collaborating with certain customers, developing and jointly implementing new innovative solutions.

We have successfully worked with VARIODRIVE multiple times to transform challenges faced by machine builders into application-specific couplings for their customers.

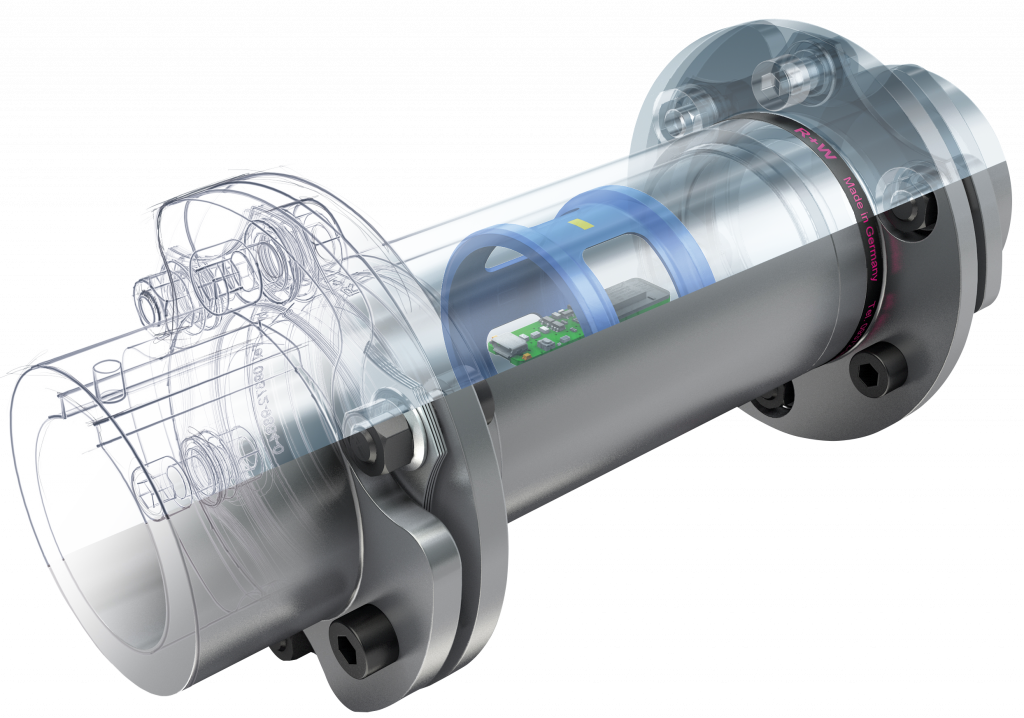

Smart Coupling for Industry 4.0

R+W recently introduced a new smart coupling with integrated sensor technology for Industry 4.0 applications – the IPK coupling. The new IPK coupling can provide real-time information to machine builders and end-users about torque, speed, vibrations, and axial forces in the drivetrain. Real-time data collection in drivetrain technology has been a challenge for years due to the difficulty of accessing rotating drivetrains with wiring and instruments. With the new IPK coupling, that challenge is overcome. This coupling technology specialist goes beyond wireless data transmission of torque, speed, vibrations, and axial force data:

“I actually hesitate to call it ‘predictive maintenance’. If my machine tells me that a bearing will fail next week and needs replacement, then I haven’t done my job well. No, the promise is that our software will advise you to opt for 100% load instead of 120%, ensuring the machine operates smoothly for the next 2 years without any problems, and the bearing requires no maintenance. We’d rather optimize than just prevent downtime.”

R+W provides its hardware and software for accessing this data, while also not ruling out the possibility that OEMs or machine builders might combine this data with information from other components and integrate it into their own environment/control systems.

Future

“Both R+W and our partners need to keep moving forward. We have entered a rapid phase of changes that make working in a technical environment interesting. We shouldn’t see this as a burden but rather as a beautiful challenge. We can learn a lot, it keeps us fresh, there’s room for innovation, and it presents opportunities!

For me, everything revolves around sustainability. Of course, we need clean drinking water and a healthy world around us, but by sustainability, I mean building an organization where people can work with pleasure and success for the next 20 to 30 years, even 50 years. I want to contribute to the sustainable growth of R+W so that our employees, partners, and customers can rely on that. Our partners, like VARIODRIVE, also have a role in this – it’s a journey we must undertake together. We need to nourish each other, including with knowledge and data.”

VARIODRIVE has been partnering with R+W since its inception (over 27 years) and applies their products in a wide variety of challenging applications. If you want more information about using products like the IPK coupling with integrated sensor technology, please contact 0186 – 63 62 80 or sales@variodrive.nl to schedule an appointment.