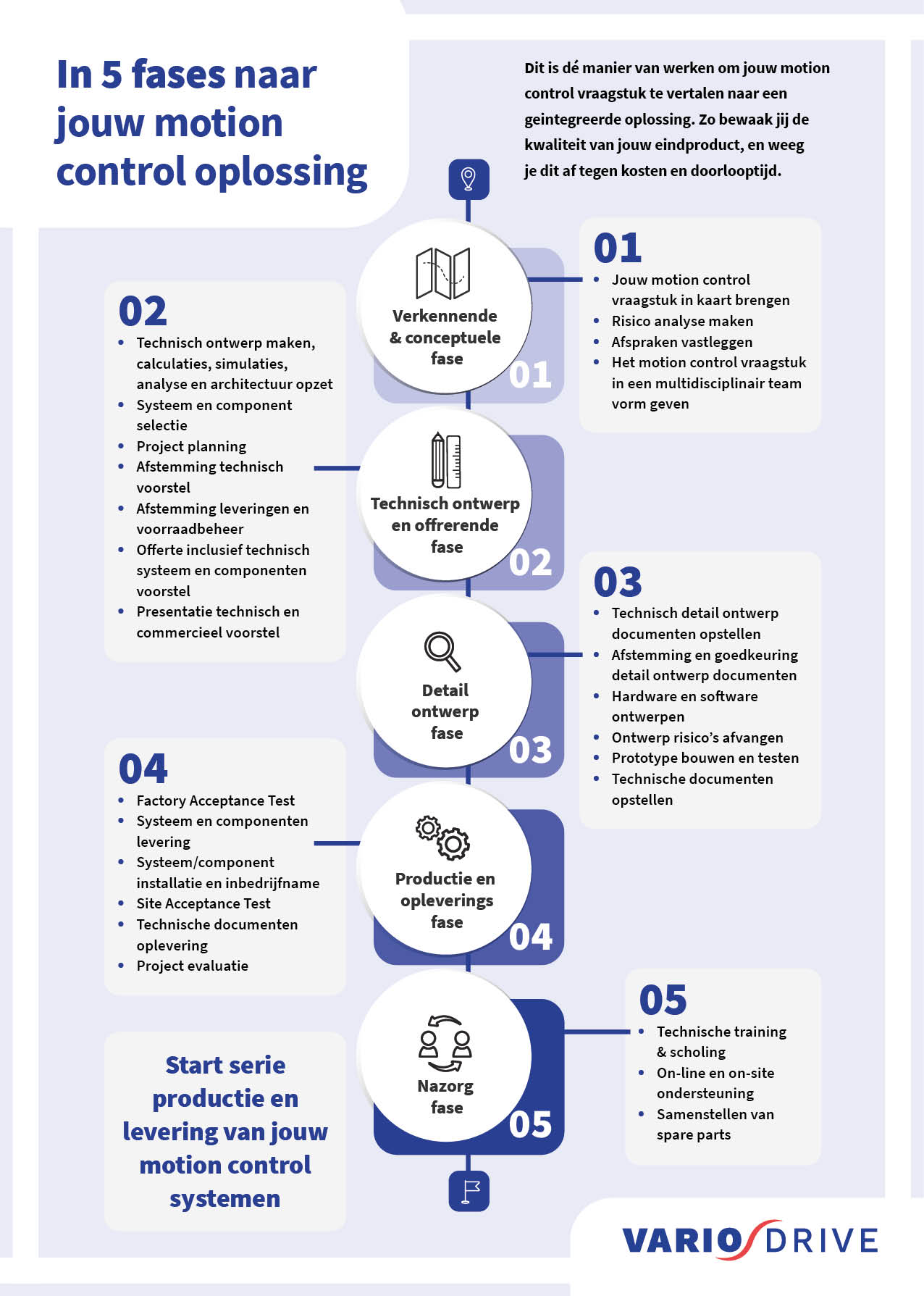

Product Development: 5 Phases to a Motion Control Solution

How do you strike the optimal balance between the technical and commercial aspects of your motion control solution? Given the rapid developments in motion control and the multitude of systems and solutions available, achieving this balance is crucial. VARIODRIVE supports machine builders throughout every phase of their product development, sharing expertise and knowledge to make it possible. Together, we ensure that the series production and delivery of your machine with motion control systems has a solid foundation. In this article, we explain how this process works for each phase.

Product development and subsequent series production are the core processes for machine builders. The proper implementation and integration of motion control systems are essential elements that can make a difference. Simultaneously, this market is rapidly evolving, offering a wide array of possible solutions. VARIODRIVE helps machine builders navigate this exciting world. We add value in every phase of your process and briefly explain what this means below.

Of course, we’re more than happy to discuss all of this in person. If you’re open to that, please contact us at sales@variodrive.nl or via +31 186636280, and we’ll schedule a (online) appointment quickly.

Exploratory & Conceptual Phase: Choosing the Optimal Motion Control Solution

In this exploratory and conceptual phase, VARIODRIVE engages in discussions with the machine builder to jointly select the optimal solution for the motion control challenge. This means looking ahead and considering both the technical and commercial implications of certain choices. We conduct a risk analysis and document the agreements made.

Since motion control challenges often intersect with various disciplines, it’s important to approach potential solutions from a multidisciplinary perspective. VARIODRIVE provides expertise from different fields to collaborate with your design department in arriving at an optimal solution.

“The significant advantage for machine builders when they involve us in the project during this phase is that we enable the team to quickly conduct a solid cost-benefit analysis,” explains Edgar Hogervorst, Sales Manager at VARIODRIVE. “We know exactly what solutions are available in the market and how that affects this specific solution. We often use our experience with similar solutions to prevent machine builders from opting for overly expensive or complex solutions. Together, we always consider the bigger picture and discuss whether initially cheaper components won’t lead to much costlier software integration later, for instance.”

Technical Design and Quotation Phase

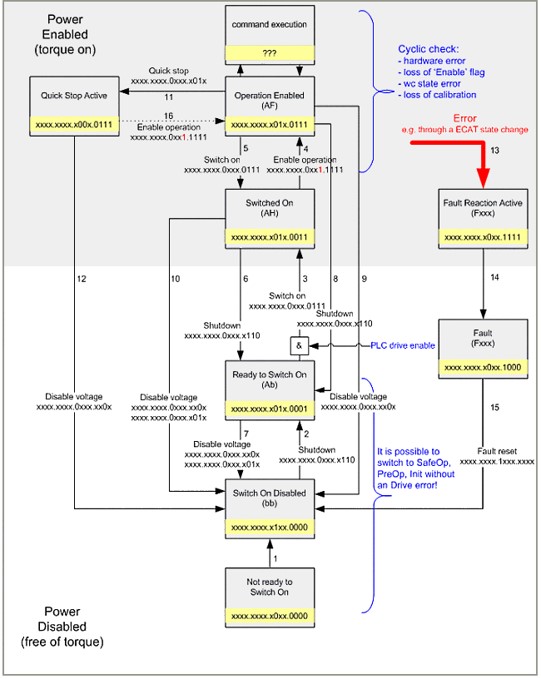

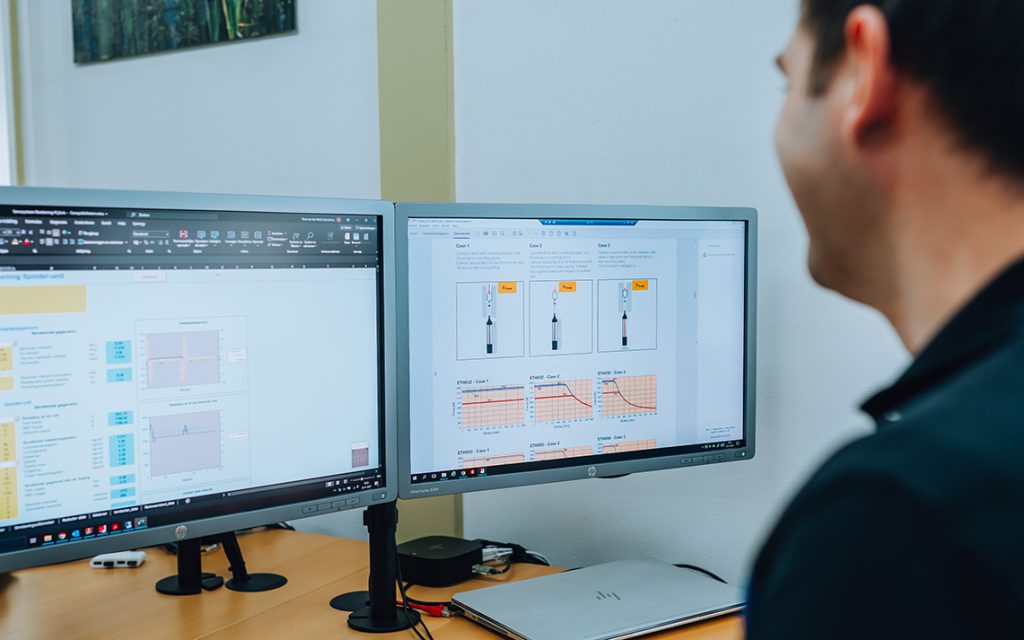

Once the general solution is established, the focus shifts to feasibility and, ultimately, a quotation. This begins with a technical design that involves calculations, simulations, analyses, and final architecture determination. Based on this, system and component selection takes place, project planning is aligned, and a quotation is prepared, including a proposal for technical systems and components. This process involves extensive calculation since various factors from different disciplines (such as mechanical, electrical, thermal) each have their own influence on the selection.

“VARIODRIVE has unique and direct contacts with the R&D departments in the factories of the various brands we represent,” says André de Lijser, Managing Director of VARIODRIVE. “If we find that a standard product doesn’t meet the requirements, we have the opportunity to collaborate with those engineers. Together, we often arrive at the desired solution, which might involve modifying or producing a standard product differently in the factory. This custom approach has frequently allowed VARIODRIVE to make a difference.

VARIODRIVE takes responsibility for the motion control system and everything associated with it. Depending on the collaboration format, this phase may not always be linear; sometimes, we gain new insights that shed a different light on previous decisions. It’s an iterative process that brings us closer to the optimal solution each time. This is also why VARIODRIVE provides a system guarantee with the quotation: a guarantee that the solution will indeed function as discussed.

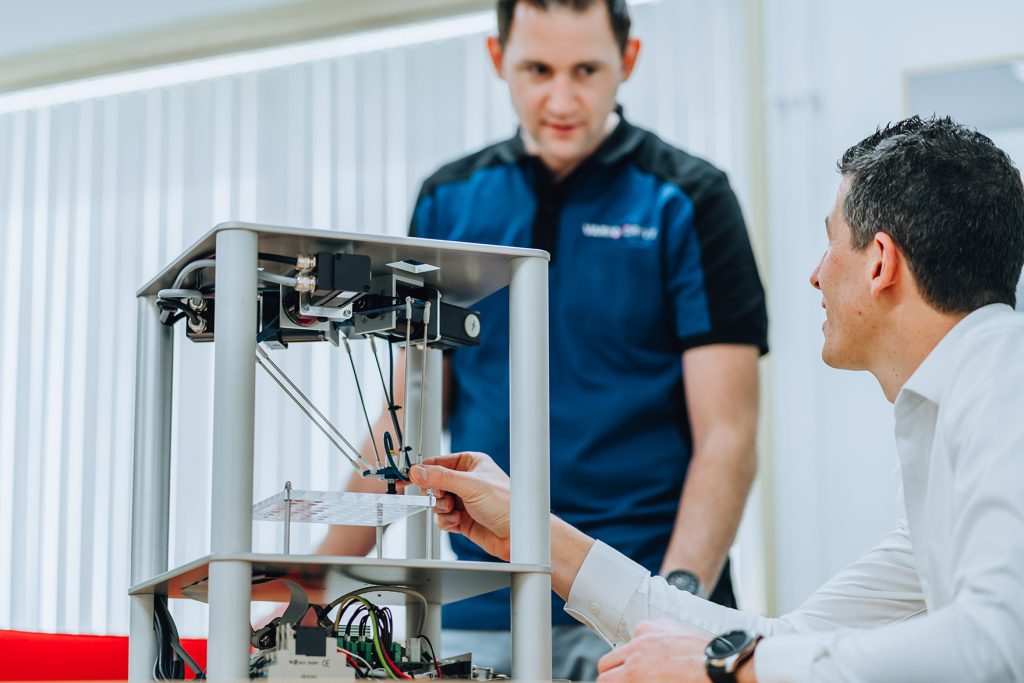

Detailed Design Phase of Motion Control Solution: Hardware and Software Design

VARIODRIVE helpt bedrijven van concept en technisch ontwerp tot aan realisatie en zelfs training van engineers

The way this phase unfolds varies from project to project in practice. VARIODRIVE distinguishes several possibilities:

- Assisting with detailed technical design (hardware and software)

- Software design and development

- Addressing design risks

- Building and testing prototypes

- Technical documentation

Depending on the problem and the established solution, VARIODRIVE carries out tasks for which it is responsible and offers support where necessary for implementation. In one project, this could involve final component assembly and delivering software integration. In another project, we might assist with detailed technical design, collaborate on building a prototype, or offer other types of support. Our involvement is determined by the needs of the machine builder.

A consistent final step in this phase is the delivery of technical documentation, which includes everything the machine builder needs to put the solution into use and maintain it. The specific requirements for this documentation are defined in the agreement, and VARIODRIVE creates this documentation based on our extensive experience. As we often take on maintenance and service responsibilities, it’s in our best interest to facilitate smooth daily use and maintenance.

[fl_builder_insert_layout id=11234]

Delivery Phase

Whether it’s a test setup for testing specific hardware or software, or the construction of subsystems, VARIODRIVE has the capabilities for these tasks. Components are assembled, tested, and validated according to agreed protocols.

The delivery process always adheres to specifications and the machine builder’s requirements. Through various acceptance tests, assembly and commissioning, documentation delivery, and evaluation, the realization process comes to an end. Common steps in this process include:

1. Factory Acceptance Test (FAT)

2. System and component delivery

3. System/component installation and commissioning

4. Site Acceptance Test (SAT)

5. Delivery of technical documentation

6. Project evaluation

The delivery of technical documentation and the project evaluation are particularly important for VARIODRIVE. As we often have longstanding relationships with our customers, machine builders, and end clients, we tailor our approach and processes to their needs. This also helps us provide the desired after-sales support.

After-Sales Phase

Technical training and education for technicians and mechanics are crucial aspects for VARIODRIVE. We ensure that the employees of our customers are trained to work with all aspects of the provided solution or chosen system. This makes them self-sufficient in handling all aspects of the delivered motion control systems, ensuring the continuity of their serial production.

Additionally, we often observe that our customers, after receiving training, can extract more value from a particular system and apply it to other applications in the future. By collaborating with us, companies enhance their own motion control competency.

Naturally, as we provide a system guarantee, VARIODRIVE offers both online and on-site support to machine builders. We also work closely with procurement and logistics departments to ensure that the right amount of spare parts is available at all times.

Serie Production and Delivery of a Motion Control System

VARIODRIVE adds significant value to machine builders in every phase of their product development. From exploration to delivery and after-sales support, VARIODRIVE provides the motion control expertise that makes a difference both commercially and technically. We ensure that the series production and delivery of your motion control system are built on a solid foundation.

If you’re interested in understanding how VARIODRIVE can tailor its services to your team or organization, have a conversation with us through sales@variodrive.nl or +31 186636280. We’d be happy to share more about our approach using a range of practical examples.