Boosting Innovation in Motion Control with AMER Brushless Motors

What’s the value of a customized motion control solution? In this article, we delve into our collaboration with the Italian company AMER, a leading manufacturer of motors, traction, and control systems. VARIODRIVE has been working closely with AMER for years to deliver unique, tailor-made solutions for challenging motion control applications.

“Our solutions are entirely customized, which fascinates me and everyone on the team. Each product is a new project and vice versa. There’s a lot of investment in products and processes, which is truly inspiring and the reason why AMER continues to grow and develop in industries with increasing technological content.”

Co-designing AMER Products

The AMER team is clearly passionate about their work for the manufacturer of motors, traction, and control systems and is eager to discuss collaboration with partners like VARIODRIVE:

Lorenzo Venegoni, Export Manager of Amer Spa, says, “We design our products together with our partners. This means they are involved right from the start of each project, and together with them, we study the peculiarities, variables, and performance of each solution. Due to the high quality level of our custom-made products, distribution takes place through Amer Group companies with a global presence. The only exception is VARIODRIVE, which represents us on-site and maintains personal contact with customers.”

VARIODRIVE explores the market and shares customer needs and new opportunities with us. Amer and VARIODRIVE collaborate to design and personalize new products. VARIODRIVE is responsible for maintaining relationships, both commercial and technical, with customers.”

Collaborating on Custom Solutions

VARIODRIVE’s Sales Manager Edgar Hogervorst also praises the collaboration with AMER:

“It all starts, of course, with the very high quality standard set by AMER in combination with the tailor-made solutions. This can only happen through close collaboration. Our technical specialists often communicate directly with AMER’s R&D department, and for larger projects, we frequently assemble a project team representing Amer, VARIODRIVE, and the customer. Everything, from mechanical design to the final labeling, can be executed according to customer requirements.”

“Our close collaboration with AMER offers numerous possibilities for VARIODRIVE’s customers.”

Brushless motors

The R&D team of Amer focuses, among other things, on brushless servo motors. The efficiency of this technology not only allows for reducing the battery size but also extends the machine’s operating hours. This opens up new possibilities for Amer and our customers in developing and designing new machines. Lorenzo states:

“Brushless technology enables increasing output at the same power, ensuring smooth operation even at low speeds, handling heavy loads and power peaks, all while maintaining system integrity. Low power consumption and long battery life increase operating hours and reduce periodic maintenance, resulting in lower operational costs.

Our brushless motors deliver power ranging from 100 to 3,500 W and are increasingly compatible with connected products that enable remote monitoring and preventive maintenance.”

By utilizing MOD-bus and CAN-bus communication protocols, Amer’s products can communicate with control systems using these protocols. This significantly shortens the required design time; fewer adjustments or integrations need to be developed.

Customer needs at the center

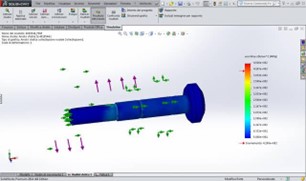

“At Amer, we can customize virtually everything according to the customer’s preferences,” says Casper Stroowinder, Technical Manager at VARIODRIVE and someone with extensive experience with Amer products. “We perform FEM analyses, tailor windings (speeds and power) based on customer specifications, and can choose between brush-bearing and brushless solutions. This allows us to always come up with a technically and commercially ideal solution in practice. The design is then delivered in 3D and PDF formats, enabling immediate drafting, and making it possible to provide and test a prototype before moving on to series production.

It’s simply too much to list – even labeling and packaging are done according to the customer’s preferences! Amer is truly a fantastic partner for VARIODRIVE. Customers of VARIODRIVE benefit from our close collaboration with this manufacturer, as we also offer customized solutions in smaller batches. This enables us to tackle many more challenges.”

The VARIODRIVE team is eager to share more about our collaboration with Amer through compelling examples of solutions we have realized for other clients. Contact us at sales@variodrive.nl or call +31 186-636280 to schedule an appointment.