Lithium batteries for construction equipment

Roel, Application Engineer

The construction industry is undergoing a major shift. While diesel has been the standard for years, more and more companies are exploring alternative power sources. Lithium batteries are playing a crucial role in this transition, making electrically powered construction equipment increasingly attractive. Stricter emission regulations and the growing demand for sustainable solutions are accelerating this shift. But what makes lithium batteries particularly suitable for construction, and why are so many companies switching to electrification?

How electrification increases equipment versatility

Not all batteries are created equal. “Some batteries are designed to release energy slowly, while others need to deliver high power in a short time. That also applies to heavy machinery,” says Roel, application engineer at VARIODRIVE. This means choosing the right battery is essential for the performance and lifespan of electric construction equipment.

A good example is a truck with a crane mounted behind the cab, where the driver keeps the engine running to power the crane. “That engine is made for driving, not for supplying energy to a crane. It causes unnecessary emissions and noise,” Roel explains. By using an electric power take-off (EPTO), the crane is powered by a lithium battery instead. This makes operations quieter and significantly reduces emissions. The same battery can also be used for other electric tools on the construction site, increasing flexibility and uptime.

In addition to improved equipment versatility, electrification offers more benefits. Construction companies are increasingly recognizing that switching to battery-powered machines is not just driven by legislation—it’s a smart long-term investment. So, what’s driving this shift?

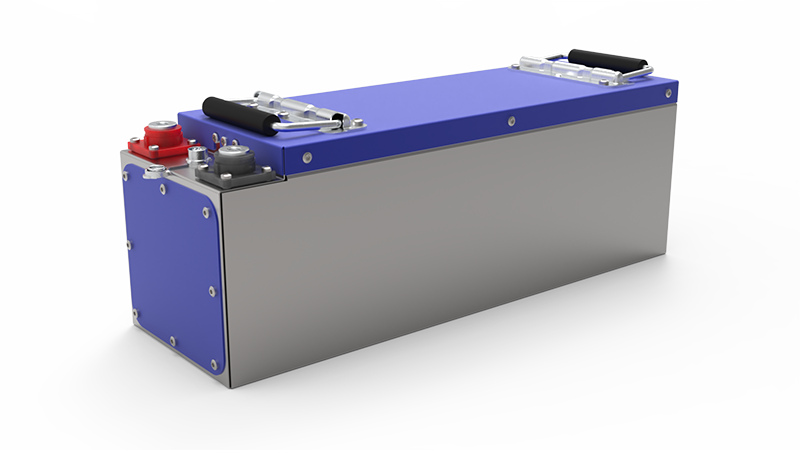

Lithium battery construction equipment

Why construction companies are switching to battery-powered machines

Besides reducing environmental impact and emissions, integrating lithium batteries brings financial advantages. Electric construction machines often come with a higher upfront cost, but they offer a more favorable total cost of ownership in the long run. Roel explains: “A lead-acid battery needs to be replaced after 300 to 600 charge cycles, while a lithium battery can last up to 2,000 cycles. You also don’t need to refill water, and maintenance is much lower. This means less downtime and lower costs over time.”

Legislation also plays a key role. Emission-free zones are being introduced in more urban areas, where diesel-powered machines will no longer be allowed. Electric machines help construction companies prepare for these changes, while also providing benefits in terms of noise reduction and ease of use.

Despite the clear advantages, misconceptions about lithium batteries remain. Many companies still question their safety and whether they are a truly sustainable alternative to traditional batteries. Let’s take a closer look at some of these common concerns.

Safety and sustainability of lithium batteries

A common misconception is that lithium batteries are a fire hazard. “The safety of lithium batteries is often questioned due to reports of fires in electric vehicles. But the LFP (lithium iron phosphate) batteries we use are chemically very stable and operate well across a wide temperature range,” says Roel. “This makes them not only safer to use but also more reliable for demanding construction applications.”

The option to charge batteries overnight also adds flexibility. “At most construction sites, there’s access to electricity, so you can charge the batteries without relying on an external generator,” Roel adds. This makes lithium batteries a practical solution for sites where machines don’t run continuously but still need a reliable power source.

More than just a battery: the expertise behind VARIODRIVE

VARIODRIVE provides tailor-made lithium battery solutions designed to meet the specific needs of our clients. With our deep expertise in electric drive technology, we deliver battery systems that are not only powerful but also sustainable and reliable.

“What really matters is that the battery is well-matched to the application,” Roel emphasizes. “That makes the system reliable, safe, and easy to use. We advise companies to help them make the right choice. This means a more efficient setup, lower maintenance costs, and optimal operation.”

Want to know how VARIODRIVE can support your construction equipment in the move toward electrification? Contact us at sales@variodrive.nl or call +31 (0)186 636280.