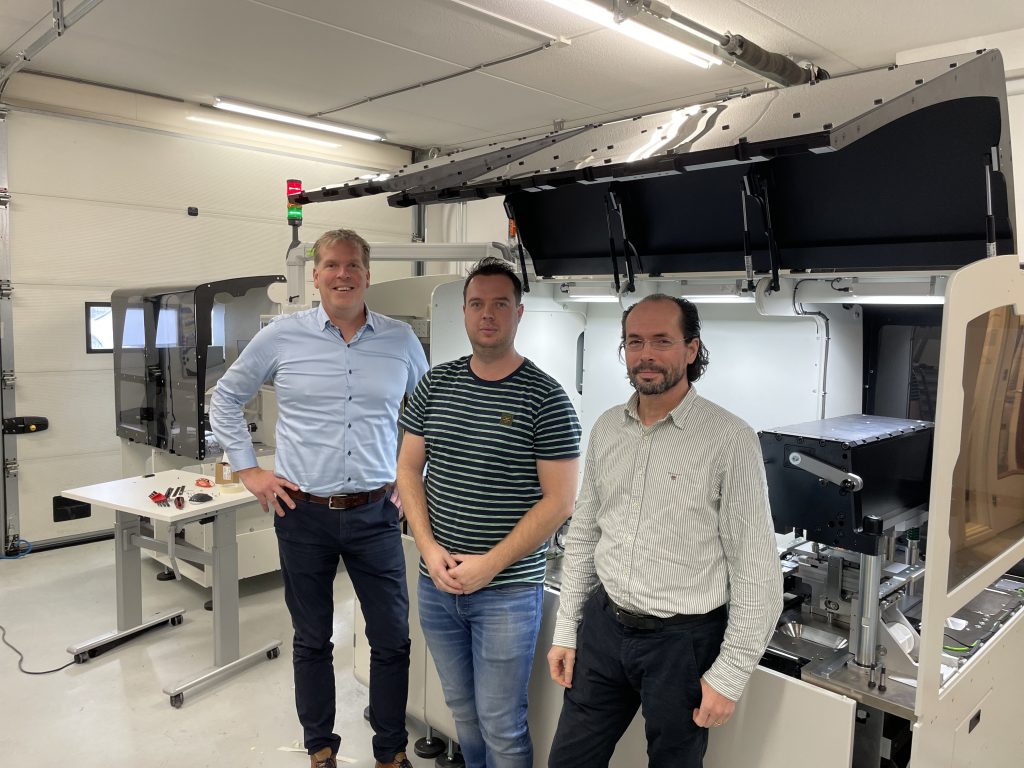

Throughput speed and flexibility are central in collaboration with Sempro.

“Previously, we primarily worked with VARIODRIVE for component selection. This involved calculating motors, selecting associated drives, cables, encoders, and so on. It also included servo tuning and getting the solution up and running. However, now our collaboration has expanded to include software, which allows us to enhance the flexibility of our machines. Michiel worked closely with Roel [van der Mark, Application Engineer at VARIODRIVE] to program the so-called CAM profiles, and this exact solution can now be applied to other clients as well. It’s great that we’ve been able to achieve this in collaboration with VARIODRIVE.” – Albert Verburg, System Architect at Sempro

About Sempro

Sempro was founded in 2003 by its current CEO, Ewald Peters, when it spun off from a company that was also involved in molding, among other activities. Since then, Sempro has focused entirely on trim & form and singulation, earning a reputation in the market as a leading specialist in this field. The team distinguishes itself through its expertise in two areas: the development of tooling and the realization of complete trim & form and singulation machines.

Tooling for Trim & Form and Singulation

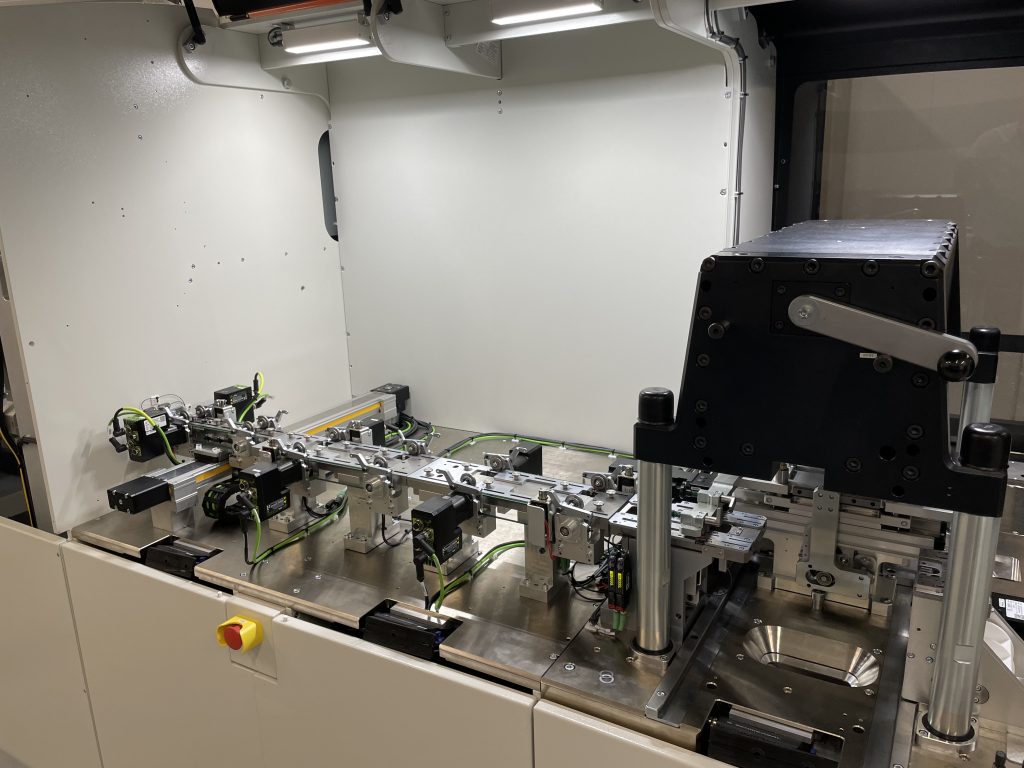

Sempro’s approach mirrors its customers’ processes and ultimately chip manufacturers. Clients come to Sempro at an early stage, during the chip development phase, requiring the right tools to test various versions of the product. Even an individual chip needs to be cut, bent, and separated before testing. These tools are developed specifically for a certain chip and require high precision. Once the process is established, Sempro can offer the automated machines that facilitate these tasks, preparing the product for mass production.

“One of the main challenges is that the different chips contain highly sensitive electronics,” explains Verburg. “Brittle materials and connections make chips vulnerable, while we need a pressing force of up to 3 tons for bending. So, we apply significant force to the chip’s leads and must prevent any damage to the product. For instance, epoxy can detach from copper (delamination), or tiny cracks can appear. Such defects might result in failure over time. We need to collaborate closely with the customer to optimize this process, based on factors like lifespan testing.”

Collaboration with VARIODRIVE

Sempro had been working with VARIODRIVE for a while, particularly in the area of component selection and servo tuning. However, with the development of a new machine, the software aspect of the collaboration has also come into play. Michiel Louis, Software Engineer at Sempro, talks about their collaboration:

“Working together with VARIODRIVE, especially with Roel van der Mark, we developed the motion around the press and the transport of the leadframes through the tool. VARIODRIVE assisted us in setting up the CAM profiles that enable the master and slave axes to be synchronized, allowing certain movements to run in sync. We used to address this mechanically before, but by now doing it based on software for the first time, we have significantly improved our flexibility. We can adjust the machine much more easily, without having to make timing adjustments in the PLC program or perform checks. In this machine, it actually results in higher throughput as well.”

Albert Verburg also expressed his satisfaction with the collaboration: “Now, not only are we looking at the motion, the axes, the mechanical design, and the force we need to apply but also how we can optimize the software control loop. And there, VARIODRIVE is definitely contributing with their expertise. Together with them, we are constantly improving the software control loops, fine-tuning them for the specific machine, and making sure everything runs smoothly.”

The collaboration between Sempro and VARIODRIVE showcases the synergy between their expertise, leading to innovative solutions that enhance both flexibility and throughput in Sempro’s machines.

Challenges

While the solution may sound straightforward, implementing it certainly presented its challenges. Michiel explains the three main challenges Sempro faced in this process:

- Communication between Two Systems: The entire motion system of the press and leadframe transport operated on a different system than the rest of the machine. Ensuring seamless communication between these two systems posed an interesting challenge.

- Lack of Familiarity with the Second Motion-PLC System: Sempro had no prior knowledge of the second motion-PLC system provided by VARIODRIVE. Additionally, the approach to working with CAM profiles, including conceptualizing and programming them, was unfamiliar to the company.

- Integration of New Servomotors and Controllers: For this first machine, Sempro had also selected a new line of servomotors and controllers, which added another layer of complexity to the integration process.

VARIODRIVE played a crucial role in providing Sempro with the necessary knowledge and advice, particularly regarding Berghof products and CODESYS software, to facilitate effective communication between the two systems. This empowered Sempro to work with the systems themselves.

Roel Van der Mark further emphasizes:

“We don’t intend to hoard this knowledge within ourselves; we are more than willing to pass our knowledge to our clients. And that worked out, as we noticed that Michiel’s questions in the software domain were becoming increasingly complex. It will be exciting when Sempro starts asking questions that even require us to conduct research to provide answers. We had already discussed the Motion PLC earlier because Sempro wanted to log data at high speeds due to short cycle times. In response, we demonstrated some aspects and planted the seed for the CAM profile approach. At that point, the limitations of the existing control system were becoming apparent, and it was clear to me that a different concept was needed to further increase speed. The challenge for me was to raise the flag in a timely manner when it was time to change course. The opportunity came when Sempro requested a heavy-duty servomotor for a new press. I knew it was time for us to take the time to explore this together. We didn’t see this as a one-time solution but wanted to enable Sempro to apply this approach in other systems in the future.”

Sempro’s Outlook on the Future

When asked about exciting challenges for the future, the Sempro team quickly responds:

“We have so many interesting inquiries at the moment that I’m confident there will be many new developments in the coming time,” says Verburg. “For instance, I’m thinking about reusing the module we developed with VARIODRIVE – the high-speed press. Additionally, we are working on new modules for a different approach to product input and output. For example, we’re developing a machine where the input and output are reversed; products will be fed in a tray and need to be removed in a cassette. This is exciting to develop because it’s the opposite of the current norm.”

Michiel adds: “My challenge is to optimize the movement of the product from point A to point B within the machine, ensuring it’s efficient and fast once the machine is mechanically set up. This involves a lot of software development. It’s reassuring that VARIODRIVE pays attention to details. They notice when we order specific controllers or servomotors and then provide input on the implementation. They are aware of the capabilities and outputs of various components, preventing us from encountering limitations during our development process. This gives us a lot of confidence in our collaboration.”

If you’re interested in learning more about collaborating with VARIODRIVE or the scope of their services, you can contact them at sales@variodrive.nl or call 0186-636280.