What is a servo motor?

Many people wonder how a servo motor works and what applications they are used for. In this article, we explain what a servo motor is, which types of servo motors there are, the functions of these types, and in which industries they are mainly used.

What is a servo motor?

A servo motor is an electric motor used in automated systems and machines that require precise positioning and control. The feedback mechanism, in conjunction with the electric motor, forms the servo motor and ensures that the motor’s position is measured and sends this information back to the controller. The controller then calculates the control signals required to bring the motor to the desired position. The motor can continuously and very precisely adjust to maintain the desired position.

Servo motors are often used in applications where high precision and control are required, such as CNC machines, robots, and packaging machines. They offer a wide range of advantages, including precise positioning, high-speed control, high torque output, and energy efficiency. Servo motors are available in various types and sizes, including rotary, linear, and AC servo motors. The right type of servo motor naturally depends on the specific application and requirements; we are happy to highlight commonly used servo motors.

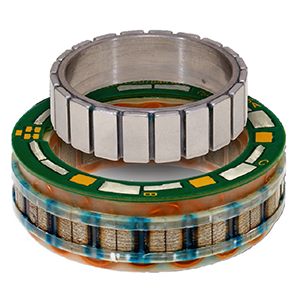

Brushless servo motor for accurate positioning

Brushless servo motors are the most common type and are used in many industrial applications. It is designed to provide precise positioning and speed through an integrated feedback mechanism that measures the angle of the rotor and feeds it back to the controller. The motor consists of a stator (the stationary part) and a rotor (the rotating part). The stator contains electromagnetic coils that create a magnetic field when current is passed through them.

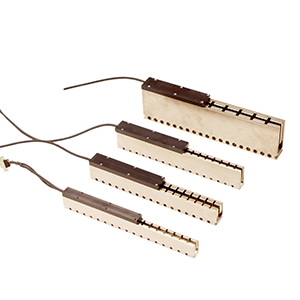

Linear actuator for precise drive

Linear servo motors are used in applications requiring linear motions, such as in the automation of packaging machines. Instead of a rotating rotor driving a shaft, a linear servo motor has a flat actuator that moves linearly over a magnetic track. A linear servo motor operates on the same principle as other servo motors, using an integrated feedback mechanism. Linear servo motors offer several advantages over other linear actuators, including higher speed control and accuracy, higher efficiency, and greater positioning accuracy.

Creating your servo motor

A kit servo motor is a servo motor whose components, such as the rotor, stator, and encoder, are delivered separately instead of being integrated into a complete housing. This provides flexibility in the design and integration of the servo motor into automated systems. Using a kit servo motor has benefits such as higher design flexibility and simpler repair and replacement of parts.

Explosion-proof servo motors

A servo motor in an ATEX environment is a servo motor that complies with the guidelines of the European Union regarding potentially explosive environments. This means the motor is designed and manufactured to operate safely in environments where flammable substances might be present. Servo motors that comply with ATEX guidelines have special features, such as housings made of materials that cannot create sparks and components designed to prevent explosions. Variodrive offers various types of ATEX-certified servo motors for applications in potentially explosive environments.

Reduced maintenance through a direct drive servo motor

With the direct drive servo motor, the moving part of the motor can be mounted directly to the load without mechanical transmissions like gears or belts. This makes the motor faster, more accurate, and requires less maintenance.

Servo motor with integrated motion controller

Servo motors with integrated electronics contain the controller electronics required to drive the motor within the motor housing itself. This reduces cabling and simplifies the design of the drive system. This type of stepper servo motor is more compact and easier to integrate into an automated system.

Working with VARIODRIVE

VARIODRIVE offers a wide range of servo motors and can deliver custom-made drive systems for industrial applications, including packaging machines, transport systems, and CNC machines. With their experience and expertise in drive technology, VARIODRIVE can assist customers in enhancing the efficiency and performance of their machines.

Do you want to know more about our various servo motors and are you curious about what we can do for you? Contact us at sales@variodrive.nl or call us at 0186-636280.