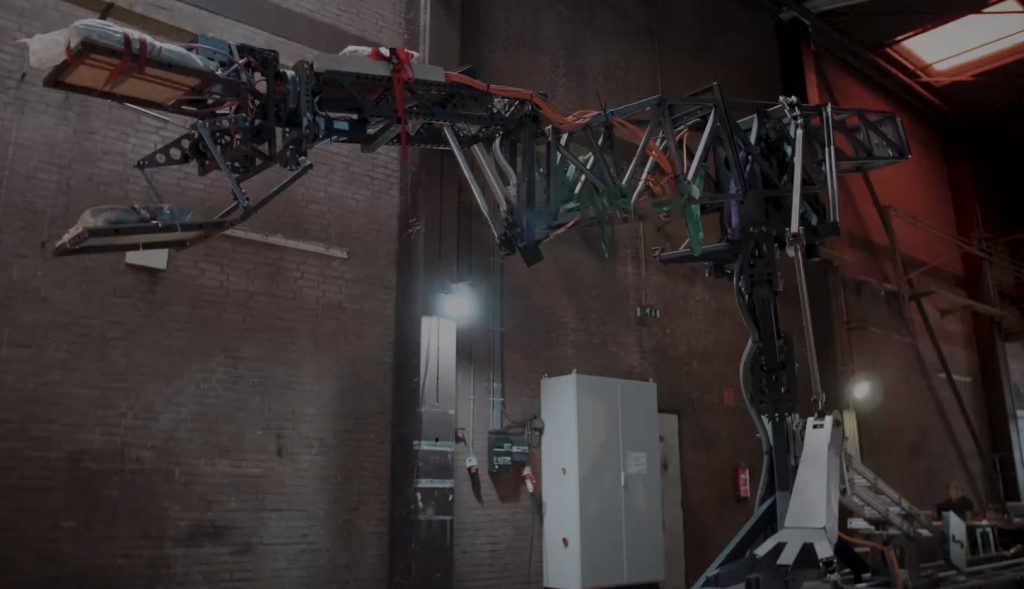

Actuator: the silent force in the animatronic T-Rex at Naturalis

How do we animate a life-sized Tyrannosaurus Rex? Berkelaar MRT, a specialized engineering firm in mechatronics, faced the challenge of creating a moving, lifelike T-Rex for the Naturalis museum. With valuable support from VARIODRIVE, they were able to select the quietest and most powerful drive for this complex project. Discover how this Delft-based company, led by technical expertise and innovative drive, took on this challenge and how the collaboration with VARIODRIVE unfolded.

“What I’m most grateful to VARIODRIVE for is that they allowed us to conduct a sort of comparative study. They provided us with many products, which enabled us to choose the best and, especially, the quietest actuator for our application,” says Wiebe Berkelaar, Owner/CEO of Berkelaar MRT, an engineering firm with a small team in Delft specializing in mechatronics for prototypes, installations, and product development—or, as Wiebe himself calls them, “peculiar devices.” The company lives up to its name, he adds:

“We’re all Delft-based engineers here, and we’re always engaged with new, challenging technology. So, we’re constantly seeking projects that demand such expertise. This request from Naturalis was a perfect match for us. Naturally, we seek out specialists who complement us, like for this project where an artist had to create the skin, teeth, and eyes.”

Building an animatronic T-Rex for Naturalis

“Naturalis had excavated a unique skeleton of the Tyrannosaurus rex. It’s a unique fossil—the only one in the world with the real skull mounted on the real skeleton, and all the bones are exceptionally well preserved and barely deformed. Many visitors come specifically for this skeleton.

However, Naturalis wanted to captivate children more. What did it look like in reality? How big was it? How did it move? They wanted to immerse visitors more in their imagination, and they planned to use an ‘animatronic’ for that—a life-sized T-Rex that could move and perform a show for visitors. It’s quite daring for a natural history museum.

Because we had done a lot for the Delft Science Center—created various setups—they approached us. And with our consortium, we won the contract.”

Key Challenges

Berkelaar’s unique approach becomes evident as Wiebe calmly discusses the main challenges, which were quite substantial:

- Installation dimensions

- Power of the system

- Noise production

“The installation dimensions, especially the opportunity to mount the actuator in line with the motor, were significant reasons for ultimately choosing the Parker ETH actuators. Of course, noise production was also a critical factor. Naturalis absolutely didn’t want a hydraulic solution due to concerns about leaks and noise from the hydraulic pump. Thus, we had to select the quietest solution that could provide enough power to move the massive animatronic.

This is where I’m most grateful to VARIODRIVE. They enabled us to conduct a sort of comparative study. They provided us with numerous products, allowing us to select the quietest actuator for our application. And that was quite a study; we quickly realized that every vibration resonates significantly through that mechanical structure. Ultimately, we made the best choice in that regard.

Oh, and the Parker actuators are equipped with a single cable, through which both motor power and encoder and brake control are transmitted. That’s a plus as well, and any reduction in complexity was very much appreciated—so that was an additional advantage.”

Collaboration with VARIODRIVE

“The collaboration was simply very pleasant. We provided a set of specs, and the folks at VARIODRIVE calculated the system and came up with advice. They not only recommended the Parker ETH spindle actuator but also advised on the winding of the servo motors/servo controller and its noise production. We had little experience in that area, and it was helpful to receive guidance. We didn’t want to run the motor at high speeds, as vibrations remained minimized up to 1,200 RPM. VARIODRIVE helped us select motors to provide more torque with the lowest possible current draw. Through the use of the Parker PSD servo controller with a high switching frequency, the noise production of the servo motor remained very low.

Of course, they ensured that everything was well-configured. We were able to adopt most of their advice directly. So, it was a very pleasant collaboration, and we’ll definitely continue to work together in the future. The quality of the setup has proven itself in practice; Naturalis recently celebrated their 10,000th show!”

Future

Through the project with Naturalis, Berkelaar MRT has received inquiries from Germany, England, and the Netherlands. Wiebe enthusiastically discusses the possibilities of taking the next step here and working with new technology:

“The animatronics we know are advanced yet somewhat simple machines that do the same thing repeatedly. It would be interesting to incorporate interaction with the audience. For instance, the animatronic could sniff at a spectator or make eye contact. Not necessarily a T-Rex, as that’s quite intimidating, but it could easily be something else. This is a software challenge we’re very eager to take on, and we’re already pitching it to potential clients.”

About VARIODRIVE

VARIODRIVE supports clients like Berkelaar MRT from concept development to realization. We leverage our expertise and share our years of experience with a wide range of applications to not only arrive at the optimal component selection but also the optimal application. Interested in learning more about our approach and how we contribute to your goals as a machine builder? Feel free to contact us for an introduction.