3-axis high-precision alignment stage with a creditcard’s footprint

A 3-axis high-precision alignment stage with the footprint of a creditcard? Motion control specialist VARIODRIVE anticipates substantial market interest in this innovative component. In this article, we delve into the technical specifications, configuration options, and potential applications of the Alignment Stage SA, showcasing its versatility and engineering excellence.

“The Alignment Stage SA by IKO, and especially the smallest type SA65DE, is unique in today’s market. Its compactness in combination with the 3-axis design and relatively large stroke length of 10mm makes for a component that can unlock opportunities for high-end application engineers.” – André Visser, IKO

Together, VARIODRIVE and IKO offer complete mechatronics solutions, including controllers and control systems, to machine builders in semicon, optics, printing, and other high-end fields. Building on the strength of both, VARIODRIVE offers the highest level of support and even customization, supported by IKO’s product knowledge and build-to-order capabilities. The Alignment Stage SA, a product from IKO, is likely to attract widespread interest and has already been successfully implemented by VARIODRIVE.

3-axis high-precision Alignment Stage SA by IKO

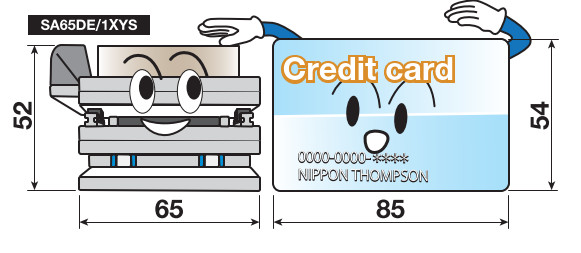

For many engineers, the immediate appeal of an alignment stage capable of XYθ-movements, especially one with a footprint smaller than a credit card, is undeniable. Add to that the possible stroke length – 10mm for the SA65, 20mm for the SA120 and SA200 – and the Alignment Stage SA becomes a component that unlocks significant opportunities.

The SA65DE is incredibly compact, smaller than a creditcard

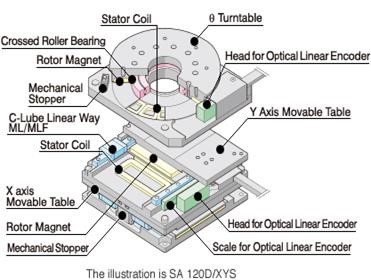

Like many IKO products, the SA benefits from being powered by direct-drive motors employing the moving-magnet principle. This design choice bestows a significant advantage: the elimination of moving cables within the application. The absence of such cables not only reduces the risk of wear and tear, potentially extending the lifespan of the system, but also enhances reliability by minimizing mechanical failure points. Furthermore, in high-tech applications where precision and minimal interference are paramount, the reduction of movable parts can significantly improve accuracy and operational smoothness. This approach simplifies maintenance, enhances system durability, and supports the creation of more compact and efficient designs, crucial for advanced technological integrations.

Repeatability

Edgar Hogervorst, Sales Manager at VARIODRIVE, underscores the critical role of repeatability, highlighting that the SA alignment stage not only meets but exceeds expectations in this crucial area:

“The SA alignment stage from IKO sets a new standard in precision with its remarkable repeatability of up to plus or minus half an arcsecond for the rotation and up to 0.5µm for the X and Y movement. This level of precision is particularly critical for high-accuracy positioning applications, where the assurance of consistent return to the same position with exact accuracy is a pivotal aspect for users. Consider, for example, a printing application that requires the layering of materials: the ability of the SA alignment stage to return to the exact position after each movement ensures that layers are deposited with unparalleled precision. This consistency minimizes the risk of misalignment and guarantees that each layer perfectly overlays the previous one, an essential requirement for achieving the highest quality results in advanced manufacturing processes.”

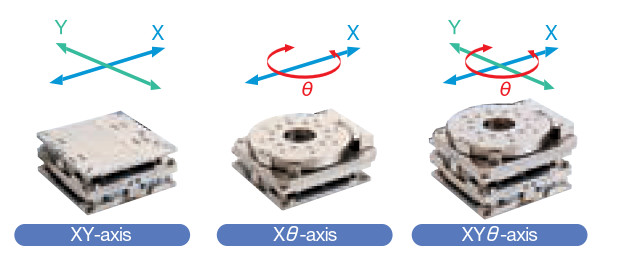

Alignment Stage SA is available in three configurations

Configuration

IKO presents three distinct configurations for the Alignment Stage SA: the XY-axis model, the Xθ-axis option, and the comprehensive XYθ-axis version. The X and Y movement is equiped with C-lube lubrification system of IKO and because of that maintanance free for 20.000KM.

In addition to these 3 configurations, IKO allows for additional customization in order to meet even the most stringent requirements. For those intrigued by the potential for customization, or if you are developling an applications that operates on the bleeding edge, engaging with a VARIODRIVE representative is highly recommended.

For additional information or to discuss the application of the Alignment Stage SA or other IKO products, please contact ehogervorst@variodrive.nl or call +31 (0)186-636280.