Why CODESYS: the benefits for machine builders

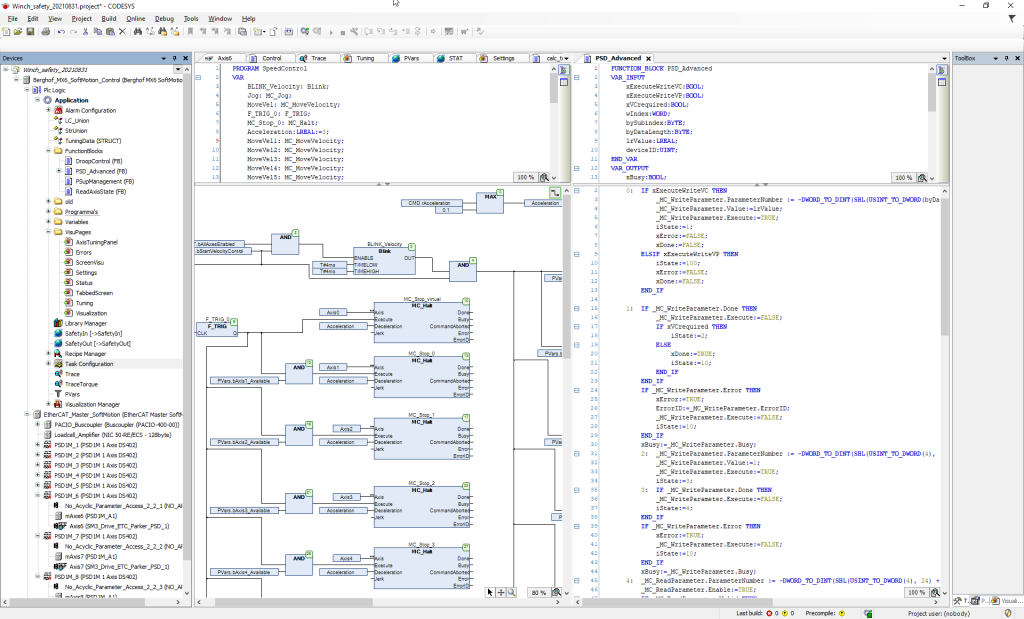

Why should every machine builder switch to the CODESYS programming platform? This open software development platform is the answer to the challenges faced by modern machine builders. The demand for machines is not only growing, but the complexity of applications is also increasing, making software play an increasingly important role. Additionally, designing and realizing machines cost-effectively is becoming more complex. In this article, we explain why VARIODRIVE prefers working with CODESYS and what benefits this platform offers to machine builders.

CODESYS is a hardware-independent programming package for industrial automation. Essentially, it provides two advantages: the machine builder has the freedom to choose which PLC to use, and the software engineer works consistently with the same software, regardless of the hardware. For VARIODRIVE, this has been the key factor for primarily working with CODESYS because we aim to offer our customers the solution that best fits their needs.

“In our designs, we look for the best possible combinations of various components to create cost-effective solutions for our customers. For less challenging processes and drive issues, we prefer a less powerful PLC to not only meet the specified requirements but also to build cost-effectively. The CODESYS software allows us to compare and combine various components effectively.” – André de Lijser, Managing Director VarioDrive

For this article, VARIODRIVE spoke with Tim van Heijst of Extend Smart Coding, the CODESYS distributor in the Benelux. Extend Smart Coding is our partner when it comes to training and educating machine builder employees in working with CODESYS software. Together, we ensure that your team not only has the optimal motion control solution but also the ability to program and maintain it themselves.

6 Reasons to Choose CODESYS

However, there are more advantages that speak in favor of CODESYS:

1. CODESYS was developed according to the IEC 61131 standard, meaning it adheres to PLC Open guidelines.

2. The software is relatively easy to work with; both experienced and inexperienced programmers can use CODESYS effectively.

3. Entry is also simple in terms of costs; the basic software is free and allows for programming, testing, and simulation at no cost.

4. The software is versatile for various types of solutions, including PLCs, motion control systems, and visualization.

5. CODESYS is an all-in-one software development platform, including features for graphical displays like an HMI panel, machine safety setup, and I/O configuration.

6. Many advanced features are fully integrated into CODESYS, such as a test manager, version control tool, and the ability for object-oriented programming.

Evolution towards PLC Open Programming

We would like to further explain the PLC Open standardization, as we anticipate that this standardization will become even more crucial in the future to meet the changing demands in the field of machine building.

In the past, a PLC was essentially a control box between the actuator and the mechanical solution. With a simple if/then command, continuous checks were made to determine if action from the installation was required. However, as applications became more complex and the desire for automation increased, the requirements for PLCs and programming software also changed. Due to the absence of a standard, manufacturers developed their own software to program the components they designed. This led to a “vendor lock-in,” where a machine builder chose the program and software package from one manufacturer, effectively excluding components from other suppliers. But applications and machines are becoming increasingly complex, and at the same time, software is becoming more important. More than ever, a “vendor lock-in” limits both the machine builder and the end user.

[fl_builder_insert_layout id=11234]

PLC Open and the IEC 61131-3 Standard

The standardization of PLC Open and IEC 61131-3 has emerged from the need for a more user-friendly way of programming PLC applications. This standardization has defined aspects such as setting up a structure, declaring variables, and using programming languages. Many software programming packages can now be programmed according to the IEC 61131-3 standard, but this does not (yet) apply to all brands. Two significant advantages of IEC 61131-3 standard software are: 1. accessibility to different types of programmers and 2. the ability to export program code from one application and import it into another.

“CODESYS offers us a lot of possibilities in the development process and design of machines. We can link components from different manufacturers together to achieve the right configuration, there are many communication options between systems, and we can even easily switch between PLCs or servodrive systems during the development process if needed.” – Roel van der Mark, Engineer at VarioDrive

Advantages of CODESYS Software for Smaller Machines and Applications

In smaller machines, the PLC often represents one of the most costly components. For instance, if a less powerful and therefore more economical PLC can be utilized, it significantly impacts the total cost of an application. The hardware flexibility offered by CODESYS allows machine builders to choose from a much wider selection of components than what can be provided by a single supplier. Particularly for smaller applications that will be produced in series, this is a compelling reason to opt for CODESYS.

Future-Proofing with CODESYS: Object-Oriented Programming

Object-oriented programming (OOP) is one of the more advanced functionalities within CODESYS, yet it is readily available. This is not yet supported by the majority of comparable software packages.

What is Object-Oriented Programming?

Object-oriented programming is a programming approach where logic is structured around objects, enabling more manageable code and reducing the impact of different software components on each other. A small change in one part of the software is less likely to create a domino effect on the rest of the software, thus decreasing the likelihood of unwanted errors or machine downtime.

OOP is a more complex programming method, primarily used in IT but gaining popularity in recent years within the field of machine building. With OOP integration, CODESYS becomes attractive to a broad group of programmers; any programmer with IT knowledge can immediately work with the software to write complex applications. This offers machine builders new opportunities, such as collaboration within the organization or with external programmers. An experienced programmer creates the building blocks for controlling the assembled components, which can then be utilized by a less experienced programmer or engineer in the application. Additionally, the object-oriented code is easier to reproduce and reuse in another application.

The First Step towards Starting with CODESYS

VARIODRIVE closely collaborates with machine builders on the motion control of applications, with software increasingly becoming a pivotal part. We’re pleased to share, through practical examples, how we combine components and software to create innovative and competitive machines, ensuring rapid development and integration. Feel free to contact our team at 0186-636280 for further information.