Goal and Structure of an Electromechanical Servo System or Servomechanism

What is an electromechanical servo system or servomechanism and what are its components? In this article, we clearly define what it is, its purpose, and how an electromechanical servo system is typically structured. As experts in the field of Motion Control, VARIODRIVE has experience with a wide variety of applications of servo systems across diverse markets. In this article, we share the basics that all these systems have in common.

Electromechanical servo systems and servomechanisms are now the standard in a wide range of applications for markets such as the metalworking industry, packaging industry, printing and press industry, food processing industry, agriculture, semiconductor, and transportation systems. Each of these markets has its own requirements and preferences – think, for example, of the ATEX directive applied in food processing applications and clean-room guidelines used within the semiconductor industry – but servo systems generally share a foundation. Before looking at a schematic example and discussing the structure of a servo system, let’s first talk about what a servo system is and why it is used.

Purpose of a servo system

The main purpose of a servo system or servomechanism is to accurately track a defined input signal by a mechanical system.

What is an electromechanical servo system

An electromechanical servo system is a system that converts electrical energy into precisely controlled mechanical movement using a closed-loop control system.

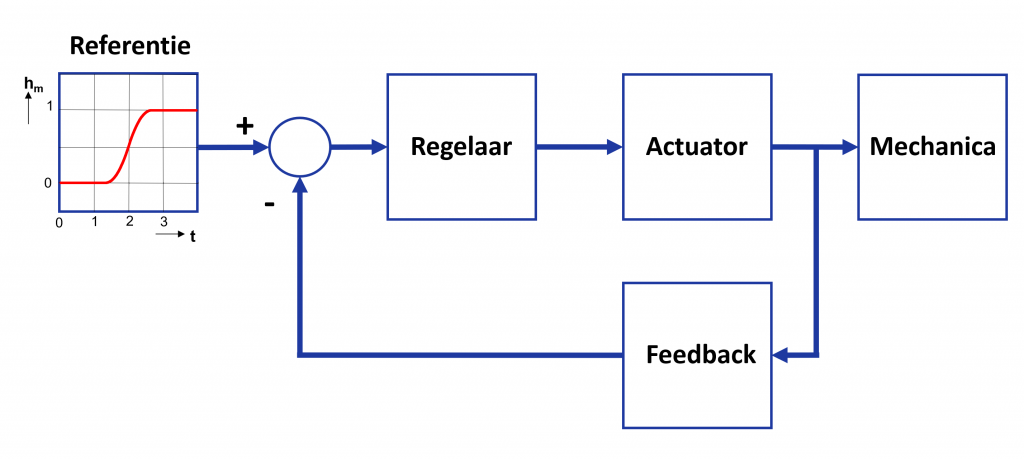

This closed-loop control system works by calculating the difference between the reference or input signal and the output signal measured from a feedback sensor. The resulting error signal (reference signal – output signal) serves as the input signal for the controller, which, in turn, drives a servo motor through an amplifier. Using this closed-loop system, we can make the output signal (the position of the servo motor) equal to the input signal (the desired position). And when there’s a change in the reference or input signal, the servo motor will follow this signal.

Example of an Electromechanical Servo System

The diagram below provides a schematic representation of an electromechanical servo system:

Structure of an Electromechanical Servo System

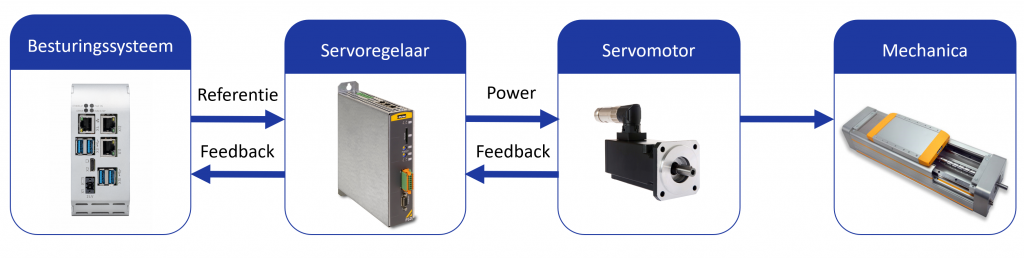

For a general and generic structure of an electromechanical servo system as depicted above, several physical components are required. These necessary components can be assembled and combined in various ways. Within a servo system, we distinguish the following components:

- An electromechanical actuator or servo motor;

- A servo controller;

- A feedback system;

- A control system.

The servo motor is the power source of the servo system. The servo motor converts the electrical power supplied by the servo controller into mechanical power. The servo controller then regulates the servo motor to the correct position at the right speed based on a defined reference or input signal. The servo controller consists of an electrical power converter and various electronic controllers for controlling motor current, mechanical speed, and mechanical position.

To achieve precise position control, the servo system includes one or more feedback systems. In most industrial servo systems, the servo motor contains a position sensor such as an encoder or resolver to measure the actual position of the servo motor. This position sensor is read by the servo controller and used to regulate the position and speed of the servo system.

The control system used for automation of the industrial machine also manages the control of the servo system. The integration of the servo system into automation usually occurs through an industrial bus system that facilitates communication between the two systems. Why is an electromechanical servo system applied? So, why and when are electromechanical servo systems used?

How can VARIODRIVE assist customers?

A machine builder aiming to implement an electromechanical servo system or servomechanism in an application often has a specific question:

They want to move a product with a certain amount of mass; in a specific time, over a defined distance, with a specified absolute and repeatability accuracy. The question is then: What do I need for this, and how can I achieve it through software and hardware implementation?

VARIODRIVE assists customers by offering the most optimal technical and commercial system configuration. We handle the establishment of a system architecture, select the optimal components, conduct necessary simulations (if needed, using a test setup), and then program the servo system. Our service doesn’t end there; we regularly provide training for those working with the application and offer the necessary service and support for many years.

Interested in how this can be tailored for your organization? Reach out to us at sales@variodrive.nl or call +31 186636280.