Explained: Feedback sensors for servo motors.

Which feedback sensor is optimal for my servo system? A frequently asked question but highly dependent on numerous factors. To provide you insight into the key considerations for selecting a feedback sensor, we’ve composed this article. We discuss what a feedback system is, the various sensors and technologies involved, and elaborate on several significant developments. It will undoubtedly assist you in choosing the right feedback sensor for your system.

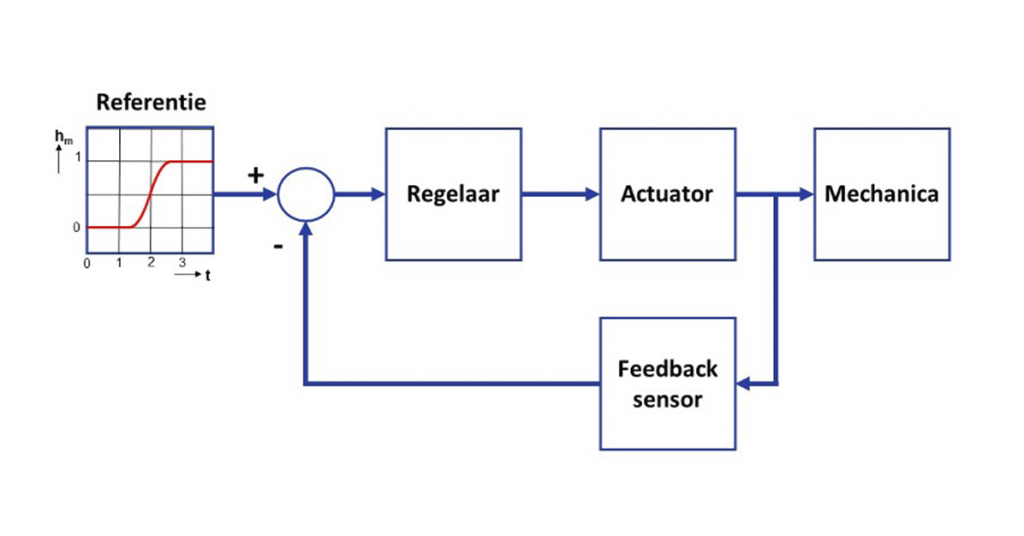

What is a feedback system?

In a mechatronic system where precise position and/or velocity control is necessary, the use of a position or velocity sensor is essential. This sensor measures the position and/or velocity to compare it with the desired position and/or velocity. Any deviation is then corrected by the servo controller.

This forms the foundation of a feedback system, where the measurement of position and velocity is crucial since the system’s performance is directly reliant on the quality of the feedback sensor.

Selection and properties of servomotor feedback sensors

When both position and velocity information are needed, a sensor that only provides position information is generally employed. The difference in position over a defined sampling period is then used to calculate velocity. If only velocity control is necessary, a speed sensor like a tachometer generator can be used.

Overview of different types of feedback sensors and technologies

The feedback signals coming from position or velocity sensors can take the following formats:

- Analog signals

- Digital pulse signals

- Serial digital data communication signals

Certain sensors use a combination of these signals to generate incremental and absolute feedback signals.

A few examples of sensors in each category include:

Analog sensors:

- Tachogenerators

- Resolvers/synchros

- SinCos encoders

- Analog hall-effect sensors

Digital pulse sensors:

- Incremental encoders

- Digital hall-effect sensors

Serial communication sensors:

- Hiperface encoders

- EnDat encoders

- SSI encoders

- BiSS encoders

In essence, most feedback sensors are available in both rotary and linear configurations. In practice, specific sensor types are utilized at different times, which is also influenced by the development of servo systems.

The practical use of feedback sensors

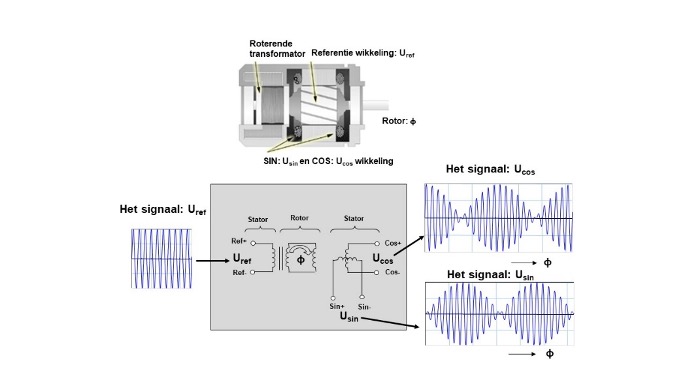

For nearly all servo systems, the need to control position is imperative. In the early days of the servo era, a synchro control transformer or a potentiometer was used as a sensor to measure the actual position. Both sensors emit an analog signal that corresponds to the current position.

In the initial industrial servo systems, DC servomotors were employed. These were equipped with a tachometer generator to measure speed and an incremental encoder to measure position. A tachometer generator produces a DC voltage signal, the voltage level of which is proportional to the speed, and the polarity is proportional to the direction of rotation.

When brushless AC servomotors were introduced, the position of the rotor needed to be measured to regulate the correct current through the motor windings. This was achieved using a resolver, for instance. A resolver emits an analog signal in the form of a modulated sine and cosine that forms an absolute signal over one revolution. Like most feedback sensors, this resolver is directly mounted on the motor shaft in the case of rotary servomotors.

Sensors with a direct digital signal

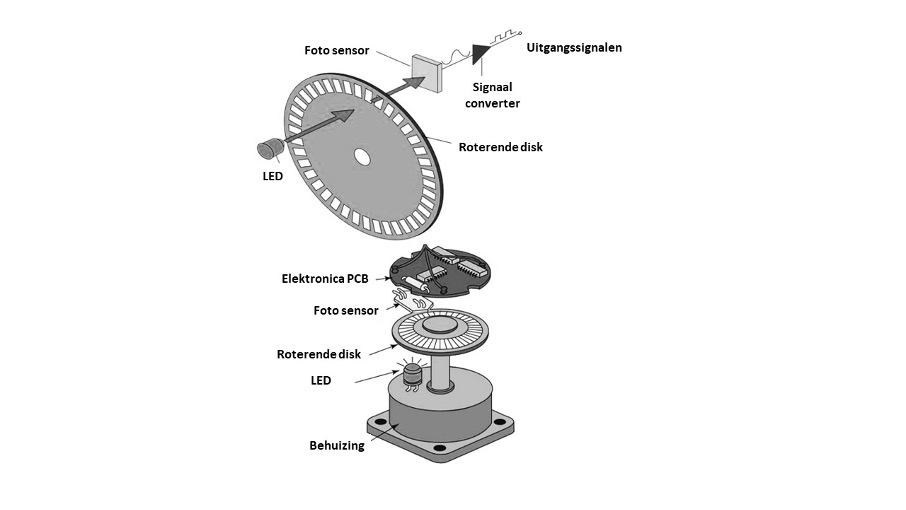

As industrial servo controllers operate digitally nowadays, analog position sensor signals are converted into digital position signals. Moreover, an increasing number of position sensors are being used that provide a direct digital signal. An extensively used position sensor is the incremental digital pulse encoder. This encoder emits digital pulses in which the frequency is proportional to the rotation speed. By adding a second pulse signal that is phase-shifted by 90 degrees compared to the first signal, the rotation direction of the servomotor can be determined.

Key parameters of digital sensor signals

When looking at the digital signals of sensors, two parameters are very important: position resolution and position accuracy. Position resolution is the smallest displacement that can be measured, the distance between two digital pulses. For example, an encoder with 1000 pulses per revolution = 360 degrees has a position resolution of 360/1000 = 0.36 degrees. On the other hand, position accuracy is the maximum deviation between the actual position and the measured position. This accuracy depends on the mechanical construction and precision with which the sensor is made.

Another important phenomenon is EMC (electromagnetic compatibility). Since feedback sensors are used in servomotors controlled by power electronics, the sensor signals must be made sufficiently robust against disturbances. Sensors with analog feedback signals are more sensitive to disturbances.

Sensors with integrated signal conversion

As the performance requirements for servo systems continue to rise, there are position feedback sensors that perform signal conversion inside the sensor and transmit the actual position to the servo controller via a digital serial connection. The advantage of this approach is that signal processing is done close to the source, reducing EMC disturbances.

These sensors are so robust that the cabling can be combined with the motor power cables. This results in less cabling in the machine, ensuring higher reliability of the servo drive.

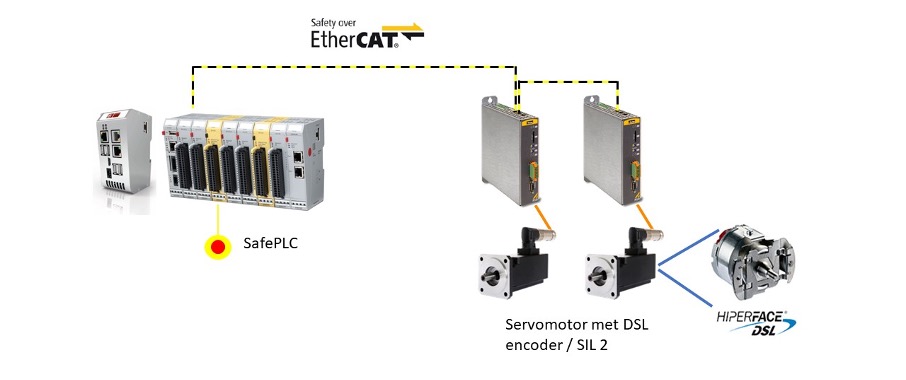

Added value of DSL Interface

The digitalization of feedback sensors has led to even more possibilities. A sensor with a Hyperface DSL interface has a bidirectional serial connection that allows data from the servomotor to be stored in the sensor’s memory. These data can be read by the controller during the commissioning of the servo system.

Additionally, motor temperature can be measured using, for example, a KTY84 sensor and transmitted to the servo controller via the DSL interface. This reduces extra wiring and prevents potential EMC disturbances through this wiring.

Because safety is a crucial aspect in machines, the DSL encoder can be integrated into the machine’s safety concept. The encoder in the servomotor, in collaboration with the servo controller, meets the Safety Integrity Level: SIL2 (IC61508) PL d.

Characteristics of feedback sensors for servomotors

In the table below, specific characteristics of some feedback sensors for servomotors are presented.

| Feedback type | Feedback signal | Resolution | Accuracy | Temp. |

| Resolver | AnalogeAbsolute over 1 omw | 16384 counts/omw. | 7-10 arcmin | -55 tot +155oC |

| Incrementele encoder | Digitale puls TTLIncrementeel | 500 – 32000 counts/omw. | 130-300 arcsec | -20 tot +90oC |

| SinCos optische encoder | Analoge sinus en cosinus 1 VttIncrementeel | 1024 periode/omw.10 bit AD conversie = 20Bits/omw. | 150-200 arcsec | -20 tot +90oC |

| EnDat3 | 2 of 4 draads serieelAbsolute over 1 omw | 19 bits/omw. | 20 arcsec | -40 tot +115oC |

| Hyperface DSL | 2 draads serieelSingle- of multiturn | 18 – 20 bits/omw4096 omw absolute | 50 arcsec | -20 tot +115oC |

| BISS-C | 6 draads serieel absoluut | 26-32 bits | 0.5-5 arcsec | 0-+55 oC |

Typical factors for selecting a feedback sensor for a specific application are:

- Desired accuracy

- Speed ripple

- Type of feedback signal

- Robustness within the environment

- Dimensions

- Costs

- Cable management

Which sensor for your servo system?

The most important question for machine builders remains: what is the optimal sensor for my servo system? The engineers at VARIODRIVE assist you by providing possible configurations during the design process. This helps you select the optimal technical configuration while considering commercial factors simultaneously. In practice, it’s also common for us to set up a test arrangement so that the requested specifications can be tested and validated.

And our service extends further. In practice, VARIODRIVE often collaborates closely with engineers in the development of new machines and applications. VARIODRIVE takes care of (a portion of) the servo technology, allowing the engineer to focus on their own expertise. This leads to greater effectiveness and reduced risk. VARIODRIVE guarantees the solutions it provides.

Interested in learning more about collaborating with VARIODRIVE? Feel free to contact us via +31 186-636280 or sales@variodrive.nl to schedule an appointment!